khj

Member

Posts: 1,524

|

Post by khj on Feb 24, 2022 1:49:34 GMT

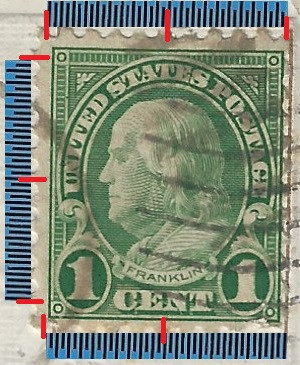

can the perf size be determined by the bottom & side mm dimensions? If we are talking about by eyeball (no ruler), only to the nearest ½ for this stamp. You can use the stamp dimensions and a ruler, but again, due to variations in stamp dimensions, such calculation would only be accurate to ¼ at best, assuming you knew if it was flat or rotary. I will provide a listing of actual wheel gauge measurements later on, so that you will understand what I mean when I say that the "10", "11" listed in the catalogs is really just a "ballpark" number. |

|

khj

Member

Posts: 1,524

|

Post by khj on Feb 24, 2022 1:56:00 GMT

OK, the blue millimeter gauge appears reasonably accurate. I am not going to bother to post the stamp dimension measurements (mainly because I forgot to save it!!!), and will go directly to posting the perforation measurement.  The red lines are ever-so-slightly off because I am using MS Paint (I know, shocking, but true) and it lacks the precision for me to mark more accurately. But it is enough to get to get you the idea. I have marked off at 10mm. Look at the left side first, you see the 10 complete holes within the 20mm (as well as 5 complete holes within 10mm). I am using a consistent perforation hole side rule in counting the complete/partial holes -- this is important, pick a reference point at one end and you must stick to it! The top/bottom are a bit tricky because the width is less than 20mm and the perfs at the top/bottom right are banged up or obscured/mangled by the side perforation holes. But you can still see 5 complete holes in the left 10mm, and at top you can see that there is a 10th complete hole (mangled by the intersection with the side perforation). I would say this is perf 10, Scott #581. My non-expert opinion. Thanks for your patience in provided so many scans. |

|

alan

Member  Inactive

Inactive

Posts: 50

|

Post by alan on Feb 24, 2022 2:02:03 GMT

Now this comment of yours got me intrigued:

"The number in parenthesis is the number of different perforation wheel gauges for that metric system gauge ID. For example, a "perf 10" BEP stamp is manufactured by BEP using one of three perforation wheels that would technically measure 9.72, 9.84, or 9.97."

If that is fact, and this stamp did not shrink while attached to the postcard, what would cause the top & bottom perfs to be technically below 9.72 or, in this stamps case, exactly 9.50 (low end) of 9.55 (high end)

Something is going on that we might be missing.

I've seen in Scott some rare instances where they make reference to a unique stamp in that era which has a different perf than the expected one.

I've spoken with the Scott folks years back and they have always been helpful.

For my part I'll bounce this one off them to have them tell me how those rare perf ones got into their book. Who determined that they were really an error perf.

The gap between 10.0 or 9.72 vs 9.50 or 9.55 is real in our study here.

Best case we are looking at an expected 10.0 vs a real 9.50.

The Scott folks know stuff nobody else know about, so let them add their muscle to our search.

Your work and analysis was impressive.

Sometimes a 2nd opinion is warranted.

Now it's my turn to do more research!

It will take time but they will respond.

That stamp dealer / expert was really baffled by this one also, so we're not alone!

Alan

|

|

alan

Member  Inactive

Inactive

Posts: 50

|

Post by alan on Feb 24, 2022 2:06:37 GMT

khj,

Thank you for chopping up my scans and doing your measurements to help make sense of this Turkey postcard stamp.

Check in periodically to find updates from me about what Scott concludes or what the experts they direct me to say.

This 1 cent green Franklin lives to fight another day!

Alan

|

|

khj

Member

Posts: 1,524

|

Post by khj on Feb 24, 2022 2:21:41 GMT

Regarding the perforation wheels used by BEP on those line perforators: | spacing (inches) | holes per 20mm | Kiusalas | Scott | | 0.095 | 8.29 | 8½-95 | 8½ | | 0.081 | 9.72 | 10-81 | 10 | | 0.080 | 9.84 | 10-80 | 10 | | 0.079 | 9.97 | 10-79 | 10 | | 0.075 | 10.50 | 10½-75 | 10½ | | 0.073 | 10.79 | 11-73 | 11 | | 0.072 | 10.94 | 11-72 | 11 | | 0.070 | 11.25 | 11-70 | 11 | | 0.067 | 11.75 | 12-67 | 12 | | 0.066 | 11.92 | 12-66 | 12 | | 0.063 | 12.49 | 12½-63 | 12½ | | 0.051 | 15.44 | 15-51 | 15 |

The 2nd column is "theoretical" what you should get if you were using digital measurement. But in practice.... paper shrinkage, production variation, blah blah... From that you can see that in reality, only the 10½ and 12½ would you expect a "near-exact" measurement using the traditional perforation gauges. The 3rd column is better known to users of the Kiusalas gauge (confess, people!). It's simply a combination of Scott perforation ID (grrrrr) and the thousandths-of-an-inch specification in column 1. Did I confuse everybody?  |

|

khj

Member

Posts: 1,524

|

Post by khj on Feb 24, 2022 2:37:44 GMT

If that is fact, and this stamp did not shrink while attached to the postcard, what would cause the top & bottom perfs to be technically below 9.72 Theoretically, that is correct -- all other factors assuming unchanged, they would measure below 9.72, even if they were produced at 9.72. Best case we are looking at an expected 10.0 vs a real 9.50. That will be an uphill climb, since the perforation wheels at BEP are fairly well documented (not as good as the British documentation). Given the shape of the upper/lower perfs, I'd be surprised if an expert didn't require some sort of proof that BEP had/used perf 9.5 wheels. But then again, I'm not an expert. So, best wishes and hoping for the best... !!!  k |

|